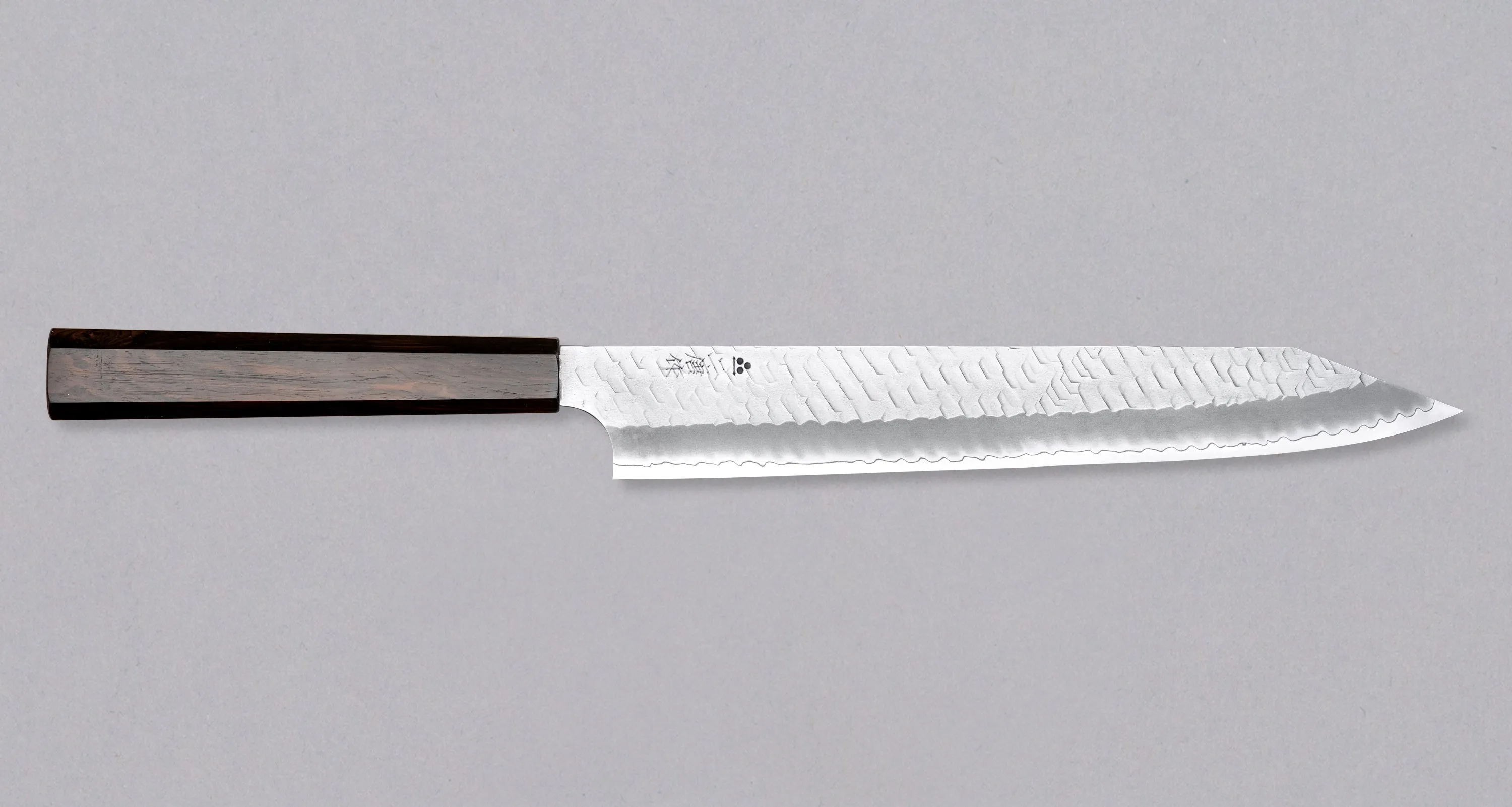

Nigara Kiritsuke-Sujihiki SG2 Tsuchime Wa Ebony 255mm is a traditional Japanese knife used for preparing meat and raw fish. Its length allows the user to slice different types of protein in one single pulling motion, which will – together with the razor-sharp double bevel blade – birth smooth, shiny cuts. The name kiritsuke refers to the tanto tip, which is, besides looking awesome, also an homage to the katana.

The hollow grind geometry of the blade, combined with the unique hammer strokes, ensures that ingredients do not stick to the blade during cutting, allowing for faster and more precise work.

Its SG2 powder steel core ensures long-lasting sharpness with little to no maintenance.

BLADE SHAPE:

The Kiritsuke-Sujihiki is a knife that establishes a clear kitchen hierarchy. As tradition dictates, the Kiritsuke knife is reserved for chefs, and it conveys a sense of control and expertise. Its long and intricate blade design makes it ideal for highly experienced chefs. The elongated blade enables long, fluid movements, while the k-tip ensures precision in cuts. This knife excels in tasks like sashimi and carpaccio preparation, as well as for precision slicing of various delicacies, allowing for thin and precise cuts.

*The length of the cutting edge is 244mm (heel to point), but with this knife the length is measured from the edge of the handle to the tip of the blade, amounting to 255mm.

STEEL:

, renowned for its hardness and subsequent edge retention—due to a high carbon (C) content of 1.5%. The steel is also high in chromium (Cr)—around 15%, which adds to corrosion resistance and Molybdenum (Mo) that improves the blade’s wear resistance. SG2 steel blades will be able to achieve a fine sharpness due to the fine microstructure of the steel and will keep it—without having to worry about maintenance and corrosion.

LAMINATION:

A high hardness of around 64 HRC means that the blade won’t be very tough, so the blade’s core was laminated using the to improve its structural integrity and subsequent ability to withstand impacts and prevent chipping. San-mai translates to “three layers” in Japanese, referring to a blade that is composed of a primary, inner layer of harder steel (hagane) and of two secondary, outer layers of softer steel (jigane) that protect the prior.

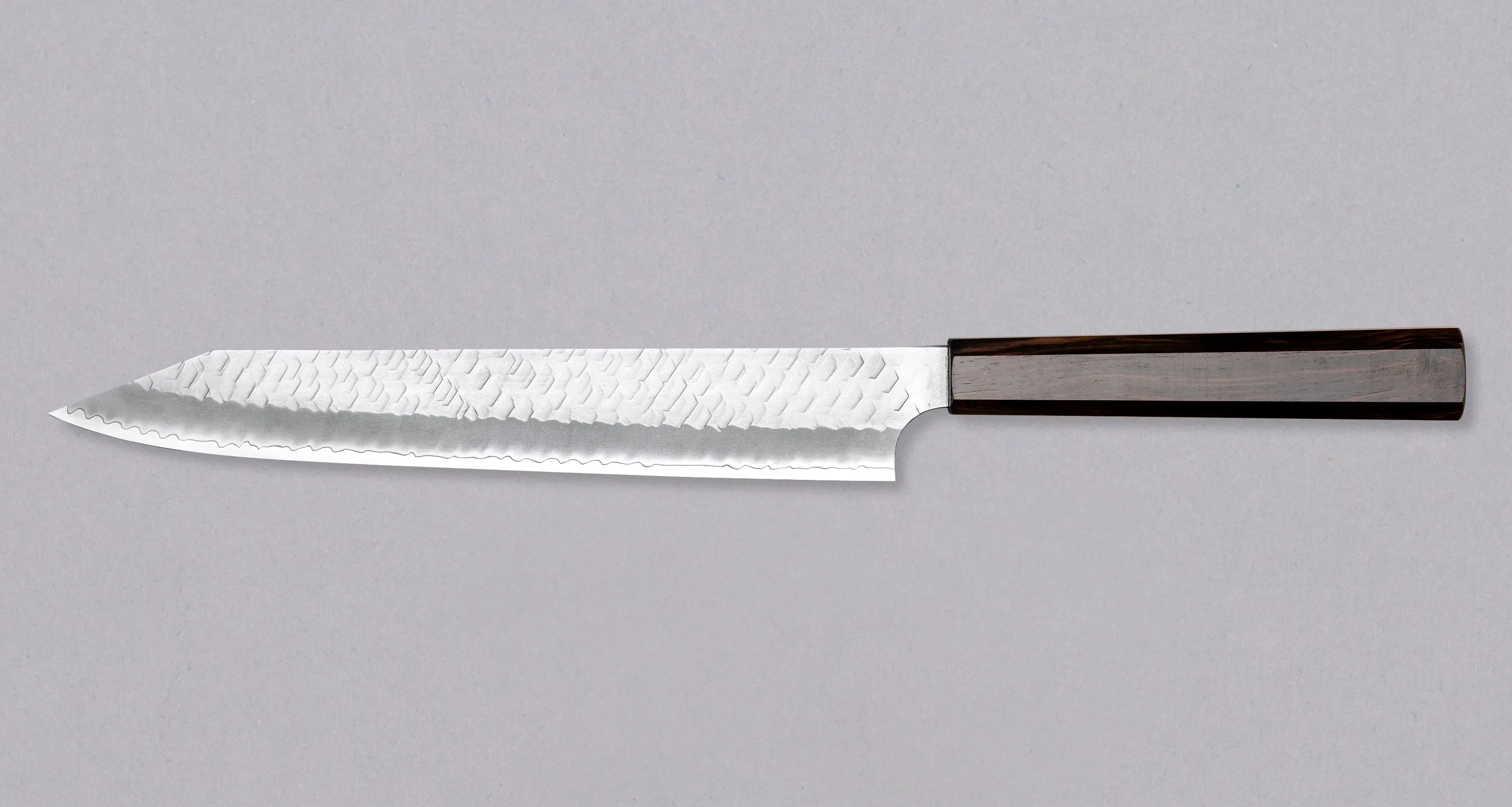

GEOMETRY:

It has a . Hamaguri grind allows superior sharpness that requires delicate handling and helps to prevent food from sticking to the blade. Such a shape keeps a lot of metal behind the edge and makes for a stronger edge, yet it still allows a good degree of sharpness. The downside to a convex grind is that it is very hard to reproduce by anyone other than a very experienced sharpener.

BLADE FINISH:

The surface of the blade was finished with a specially textured hammer that leaves complex geometric impressions on the top - this blade finish is called . Japanese hexagon hammered finish on knives is an amazing technique in which the surface of the blade is worked with a hammer to create captivating hexagonal indentations. The tsuchime surface reduces friction and prevents food from sticking to the blade while cutting. The textured surface creates small air pockets that allow for smoother and more precise cutting.

HANDLE:

The Japanese handle (Wa) is crafted from a single piece of dark without the additional ferrule. The handle is suitable for both left and right-handed users and embodies a simple Japanese aesthetic. Ebony wood is the ideal choice for Japanese handles due to its hardness, durability, and aesthetic appearance. Its rich color, visible grain patterns, and historical significance further enhance the wood's desirability and appeal.

BLACKSMITH:

has a 350-year history and has been making swords since the Edo period. Head blacksmith Tsuyoshi Yoshizawa, who works alongside his father Toshi Yoshizawa, is an eighth-generation blacksmith with a passion for art and music as well as knives, and his famous Nigara Anmon design is the result of his love of Andy Warhol’s artwork. Nigara is certainly one of the most exceptional knife makers in Japan.